MIT-SCAN2-BT

DETERMINATION OF DOWEL AND TIE BAR POSITIONS IN CONCRETE SURFACES

The MIT SCAN2-BT is a device for the non-destructive determination of dowel and tie bar positions in concrete. Working with pulse induction technology, the device makes use of the magnetic properties of the dowel bar by recording its returned magnetic field via sensors. The measurement process is very straightforward. A mobile rail system is placed above the joint to be assessed. The measuring trolley is then pulled over the rails along the joint. It is controlled via a Pocket PC that communicates wirelessly with the measuring device. During the measurement run, the Pocket PC displays the signal received and the distance covered.

Measurement and evaluation of dowel bar positions in a joint will together take less than a minute. Dowel embedment depths and misalignments such as tilt and shift can be determined precisely.

If dowel bars are implemented in baskets, the measuring method provides useful information about the presence as well as significant translations and/or distortions of the baskets.

The device is applied in concrete road construction (highways), runway construction at airports, container areas at harbors and other reinforced concrete surfaces (e.g. motorway service areas, bus stops, roundabouts, etc.).

COST-EFFECTIVE

- Fast, full analysis and visual display of measured values with the desktop software MagnoProof

- Automatic evaluation of measurement results

- Prompt determination of dowel positions permits in-process paving adjustments, e.g. changing dowel bar inserter settings

NONDESTRUCTIVE

- Measures by simple run over the concrete pavement

- Requires no core extraction for calibration or in case of concrete property deviations

PRECISE

- Accurate measurement of dowel and tie bar positions in concrete

- Precise determination of dowel embedment depth and tilt and shift misalignment

RAPID AND EFFICIENT

- Simple and fast assembly or disassembly for transport

- Simple, intuitive operation

- Immediate calculation of dowel bar positions even during a run

- Measurement and evaluation of a joint across several lanes within one minute

FLEXIBLE

- Measures independently of the degree of cure and immediately after cutting of joints

- Measures even on wet roads

- Measures on fresh concrete, as soon as it is user-walkable

SUSTAINING

- No need for a core drill reference, potential site damaging is avoided

- Free of emissions, mindful of nature and the environment

Nondestructive determination of dowel and tie bar positions in concrete via pulse induction enables the user to carry out precise, rapid and extremely economical measurements in the field.

Specifically when compared to the likewise nondestructive electromagnetic method that uses reflection (georadar), the pulse induction method implemented in the MIT-SCAN2-BT offers key advantages. Noteworthy are in particular its high measurement speed, simple and intuitive handling, and enormous versatility.

While georadar cannot be used on roads during wet weather, the MIT-SCAN2-BT delivers precise and reliable measurements even on roads that are rain-drenched. Measurement can even be taken on fresh concrete as soon as it can be walked on by the user.

In practice, the georadar system also relies on frequent core extractions, i.e. before starting measurements or when deviations occur of the concrete's properties on the measurement site. The dowel position measuring device MIT-SCAN2-BT, on the other hand, only requires an initial calibration of the type of dowel or tie bar used.

The dowel position measuring device also excels from an economical perspective: It enables users, for example, to determine the exact positions of dowel and tie bars on-site within one minute. Georadar, by contrast, requires time consuming evaluation at the office workplace.

The speed of the dowel position measurement device, therefore, not only enables large areas or road stretches to be inspected per workday, but also allows adjustments to be made during the paving process, e.g. changing the dowel inserter settings. These advantages together with the compact design, ease of use and versatility of the MIT-SCAN2-BT translate into substantially lower costs per measurement.

Valid range

The valid measurement range far exceeds the tolerance range for dowel bar positions. Outside this range, the specified analysis accuracy cannot be warranted.

| Depth | between 110 mm and 190 mm | |

| Shift | maximally 80 mm | |

| Horizontal tilt | maximally 40 mm | |

| Vertical tilt | maximally 40 mm |

Tolerances

The indicated tolerance values apply within the valid range mentioned above and in the absence of influence from foreign objects.

| Reproducibility | 2 mm | |

| Path measurement in joint direction (x) | 0.3 % ± 3 mm | |

| Absolute depth | ± 4 mm | |

| Shift | ± 8 mm | |

| Horizontal tilt | ± 4 mm | |

| Vertical tilt | ± 4 mm |

Total system

| Allowable operation temperature | 5 °C . . 50 °C | |

| Allowable storage temperature | -10 °C . . 50 °C |

Measuring trolley

| Dimensions | 116 cm x 65.5 cm x 9.5 cm | |

| Weight | 16.5 kg | |

| Operation voltage | 12 V | |

| Battery | lead gel battery 12 V/7.2 Ah | |

| Operation life per charged battery | approx. 8 h | |

| Charging time | approx. 4 h |

Rail system

| Length per rail segment | 1 m | |

| Rail width | 1.18 m | |

| Rail height | 3.5 cm | |

| Length of the system | 10 m (Standard length) |

Rail System

The rail system can variably be extended per meter. The following accessories are available.

Pipe of 1 m length

For the flexible extension of the standard rail system

End piece of 0.6 m length

Start and end of the rail system

Sleeper

For exact guiding of the measuring trolley along the joint

Screw

For joining a pipe or end piece with the sleeper

Rail case

For the safe and comfortable transport of the rail system

Accessories for measuring trolley and Pocket PC

Spare parts

- Spare battery

- Wheels

- Axles

- Spacer

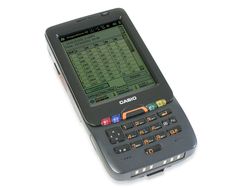

CASIO IT800 Pocket PC

Pocket PC for quick display of values during measurement

CASIO IT800 accessories

- Docking station

- Charging cable

- Spare battery

The new analysis software MIT-MagnoProof 6 is part of our standard delivery. It handles large volumes of measurement data at a desktop PC. The software has the following functions:

- Simple data transfer from mobile computer

- Effective data organization, easy file viewing and quick scrutiny of measurement data

- Effective batch processing for calculating dowel alignments from a large number of measurements

- Data output via a simple results table with combined graphical and numerical presentations of measured data and results

- Reports, summaries as Excel- or PDF-files

- Statistic function - very helpful for dowel bar inserter adjustment and for evaluating road sections

- Automatic check for interference factors

- Convenient correction of erroneous data input at the measuring site (dowel size, joint number etc.)

- Various data display methods for evaluation of complicated measurement situations

- NEW: automatic evaluation of dowel bars inserted on baskets

Clients using MIT-MagnoProof 5 and former versions, please ask for an up-date to use MIT-MagnoProof 6